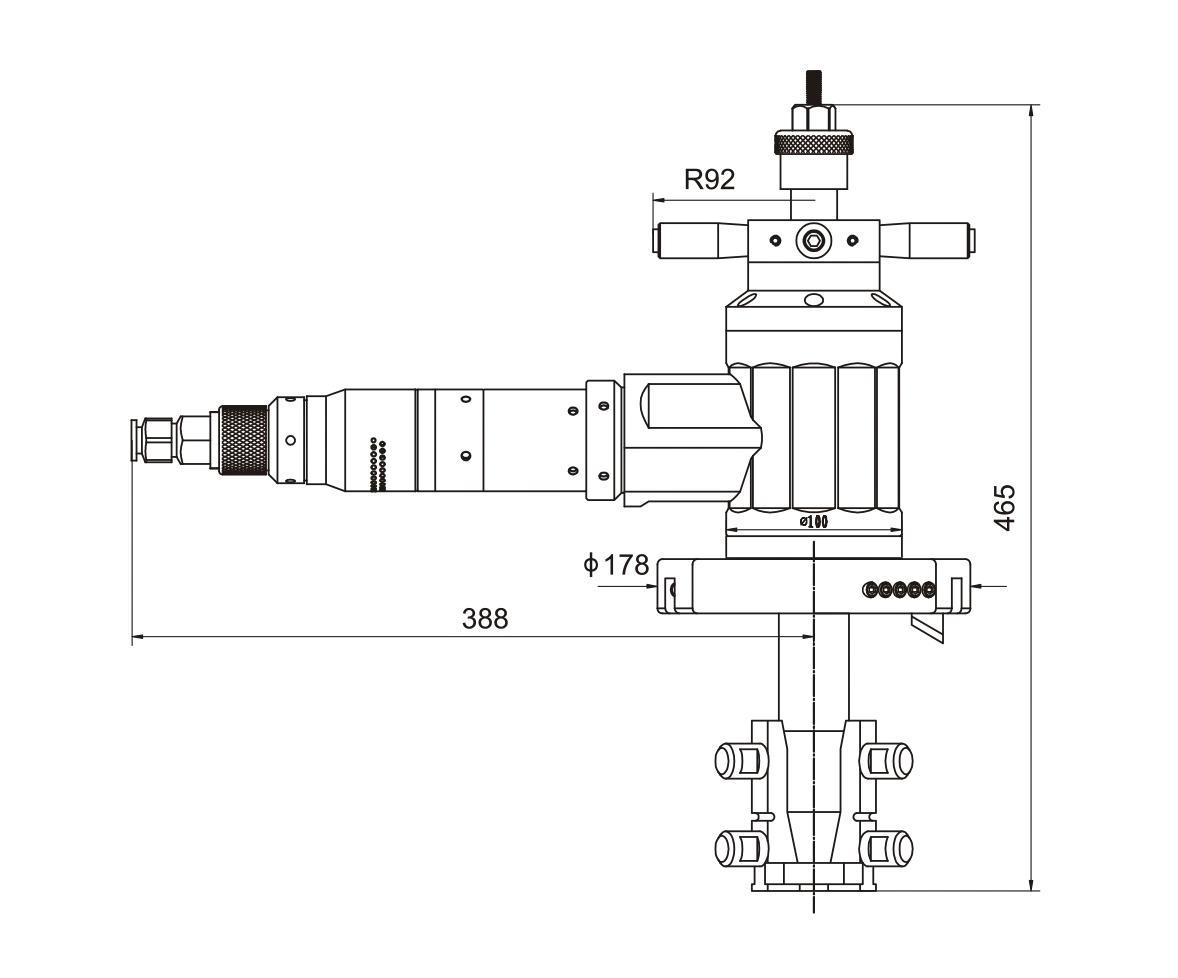

PB6 Portable Pipe Beveling Machines

EZLINK offer large range of pipe cutting and beveling machines. Pipe cutting beveling equipment for weld edge preparation of pipes is outstanding and very competitive.

Tool Bits

- Standard Tool

- V Type Prep.

- U Type Prep.

-

Facing

Inside Beveling

*Consult with us for special demand

Play Video about V1 pipe beveling machine-pneumatic

PB series is professional desiged ID mounted end prep equipment utilizes an expandable, self-centering mandrel system which mounts in the open end of a tube or pipe. Jaw blocks, corresponding to the size of pipe being worked on are placed on the mandrel. When a draw rod is tightened, jaw block bases are drawn up an inclined ramp, expanding the jaw blocks against the inside bore of the pipe. This provides a solid, torque-accepting grip for accurate machining operations.

| SPECIFICATIONS | INCH | METRIC | |

| Clamping range ID-ID | 2.36 – 6.26 in. | 60-159 mm | |

| Working range ID-OD | 2.36 – 6.63 in. | 60 – 168.28 mm | |

| Max. Wall-Thickness | 0.79 in. | 20 mm | |

| Weld prep | V Prep, U Prep, Facing | ||

| Rotation Speed | Pneumatic: | 61 RPM | |

| Chinese Motor: | 36 RPM | ||

| Bosch Motor: | 38 RPM | ||

| Power | Pneumatic: | 1 HP | 900L/Min@0.6Mpa |

| Chinese Motor: | 1050w | 220-240V 1PH 50/60HZ | |

| Bosch Motor: | 1000w | 220-240V 1PH 50/60HZ | |

| Working Weight | Pneumatic: | 16 kg | |

| Chinese Motor: | 17 kg | ||

| Bosch Motor: | 17 kg | ||

| Shipping Weight | Pneumatic: | 30 kg | |

| Chinese Motor: | 33 kg | ||

| Bosch Motor: | 33 kg | ||

| Packing: | 26.8 x 21.7 x 10.24 In. | 680x550x260 mm | |

Standard Supply:

Machine, Driven motor,

full set expanding blocks

3 pcs tool bits

(1 Facing tool, 1x30deg. Beveling, 1×37.5deg Beveling)

Why choose PB6 Pipe Beveling Machine

- Fast installation, the whole operation within 2 minutes.

- Screwing up pull-rod nut, it can make expanding block tighten the pipe, self-centering, efficiency and accuracy.

- The tight structure is changed more fast and convenient.

- New tight structure makes the machine more stable, with good rigidity and bevel quality.

- New tight structure with long life, easy to dismount, convenient to clean and maintain.

- Easy to install tool bits, it can be install and adjust within few seconds.

- Light-weight design is more suitable working for low clearance space.

- Three cutters can be arranged three tool bits for complex beveling operation at the same time.

- Aluminum body, light weight, convenient to carry it.

- Precision rolling bearing and sealed lubrication can extend using life to a maximum degree.

- It can process facing, V Type, Y type, U type, inside, seal groove and others complex beveling.

- Different driven, electric and air driven can used to all situation, especially electric driven with light weight, low noise and shake.

- Enough torque base on gear-driven with precision production, special steel and heat treatment.

-

Address:

Xinxiang Industry Zone, Weibin District, Xinxiang, Henan, China -

Mobile:

+86-17737350726 -

Email:

info@ezlinkportable.com